What is P.C.C?

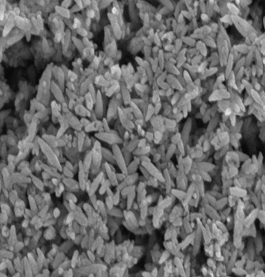

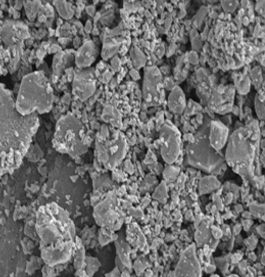

What is P.C.C?Precipitated Calcium Carbonate (P.C.C) is manufactured by the reaction of dissolved Carbon dioxide with suspension of Calcium hydroxide under varied conditions to obtain different crystal STRUCTURE, SHAPE and PARTICLE SIZE. Various properties for end use applications can be infused into the P.C.C by virtue of precise reaction controls.

The specific structure, shape and particle size of P.C.C facilitates processing of a polymer matrix and subsequently the physicomechanical properties of the end product.P.C.C is one of unique class of extender which can be classified as a multifunctional product providing an outstanding cost / performance opportunity.

The surface treated P.C.C (Activated Calcium Carbonate) allows good dispersibility in polymer mix and gives higher loading / output besides improved surface gloss, degree of whiteness and good weathering resistance.

Precipitated Calcium Carbonate Vs Ground Calcium Carbonate

PCC GCC

1. Process Precipitation & Refining Simple grinding

2. Particle Shape Rhombohedral/Scalenohedral Undefined

3. Particle Structure Calcitic Undefined

4. Particle Size Much lower ---

5. Purity >97% <95%

6. Density 2.6 (Lighter) 2.7

7. Abrasiveness Nil Present

8. Coating Uniform (Wet coated) Non-uniform (Dry coated)

9. Dispersibility Better than GCC ---

10. Whiteness >98% <96%

| EMICAL | |

| EMICAL PCC | GCC/NCC |

|

|